MOZLASER Laser Rust Removal Machine

Laser rust removal machine is specially developed for cleaning surface rust of steel plates and other metal sheets. Compared with the traditional manual grinding and chemical cleaning, laser cleaning is faster and more efficient, and pollution-free, with a simple process, plug and play.

MOZLASER laser rust removal machine also has the following features,

- Long service life, maintenance-free

- Extra cleaning width, up to 300mm wide

- Exclusive continuous laser cleaning laser head

What is the difference of MOZLASER laser cleaning machine and laser rust removal machine?

Under MOZLASER definition, the core difference between two kinds machine is that the laser cleaning machine uses a nanosecond pulsed fiber laser source and the laser rust removal machine uses a normal continuous fiber laser source.

The pulsed laser source is more expensive, but his advantage is that it can clean all kinds of different materials, metal, plastic, wood, stone, artifacts, walls, rocks, etc., without hurting the substrate.

The continuous fiber laser source, the price is cheaper,but the rated laser power is more advantageous, cleaning width up to 300MM, cleaning floating rust is fast and efficiency, but it will be continuously heating the substrate, will produce a certain thermal effect and damage the substrate.

- If you want to clean molds, car engines, cultural relics, statues and other high precision objects, we recommend you to buy laser cleaning machine

- If you only need to clean the rust on the steel plate and want to require high efficiency, then we would recommend you to buy the laser rust removal machine, we have designed this rust remover specifically for cleaning the floating rust.

Models Of MOZLASER Laser Rust Removal Machine

1000W continuous fiber laser source,special laser cleaning head for rust removal with 50-300mm cleaning width,Lightweight laser head

1500W continuous fiber laser source,specially designed rust removal laser head,independent water cooling system

2000W CW continuous fiber laser source,smart laser cleaning system ,the laser cleaning power and width is ajustable

Which Kinds of Materials Can Be Cleaned by Laser Rust Removal Machine? (5)

Moz Guarantee

Two-year warranty on the entire machine, no warranty on consumables.

After-sales service replies within 8 hours and provides solutions within 24 hours during the warranty period.

All replacement parts and shipping costs are covered by MOZLASER during the warranty period.

Our partners or engineers will provide an on-site installation training service after you purchase the machine.

The Raycus Latest Generation of Continuous Laser Source

MOZLASER laser rust removal machine adopts the latest Raycus continuous fiber laser source, the continuous fiber laser source has the characteristics of small size and high power rating, high light stability, etc. The high power laser energy beam can quickly vaporize the oxidized rust on the metal surface, and the laser spot width can be adjusted arbitrarily through the optical motor and optical lens to adapt to different rust removal environments.

And except for Raycus brand of fiber laser source,other name brand laser source is available too,like IPG,JPT,Reci and so on.

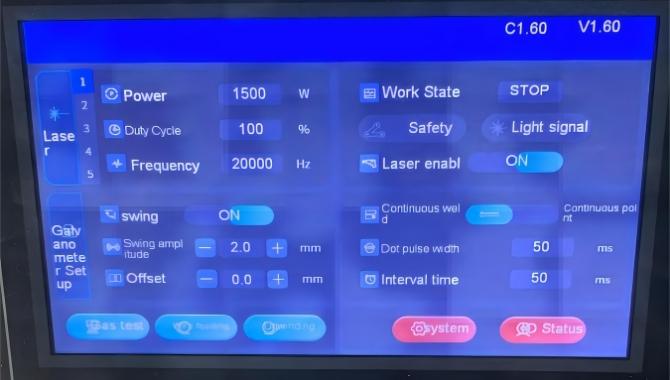

Precise Laser Power Control System

Specially developed laser rust removal system optimized for laser power control. Touch panel combined with intelligent motherboard to visualize and set parameters such as laser power, rust removal frequency, and rust removal width.

For metal floating rust, high power, high frequency, and wider descaling width can be set to increase the rust removal efficiency.

Double Wobble Galvo Laser Rust Removal Gun

This laser rust removal gun has built-in dual wobble motors. They can precisely control the width and shape of the laser beam to suit different rust thickness usage scenarios.

Laser descaling gun independent water cooling module design, can accurately control the temperature of the laser head. Avoid overheating of the laser head under high temperature scenarios and sun burst.

Continuous Development and Improvement of the Laser Cleaning Head for Laser Rust Removal Machine

MOZLASER has independent product development capabilities, through market feedback to update the structure of the rust removal laser head, and constantly improve the shortcomings exposed in the laser rust cleaning process.

In fact, there are many many suppliers of laser cleaning head in the market, but we still insist that we directly design and develop the rust removal laser cleaning head by ourself because we are in the closest contact with the machine users and know the defects of the laser head and the needs for improvement. So if we develop this laser head through our company team, then we can very quickly improve and update the technology for our laser rust removal machine.

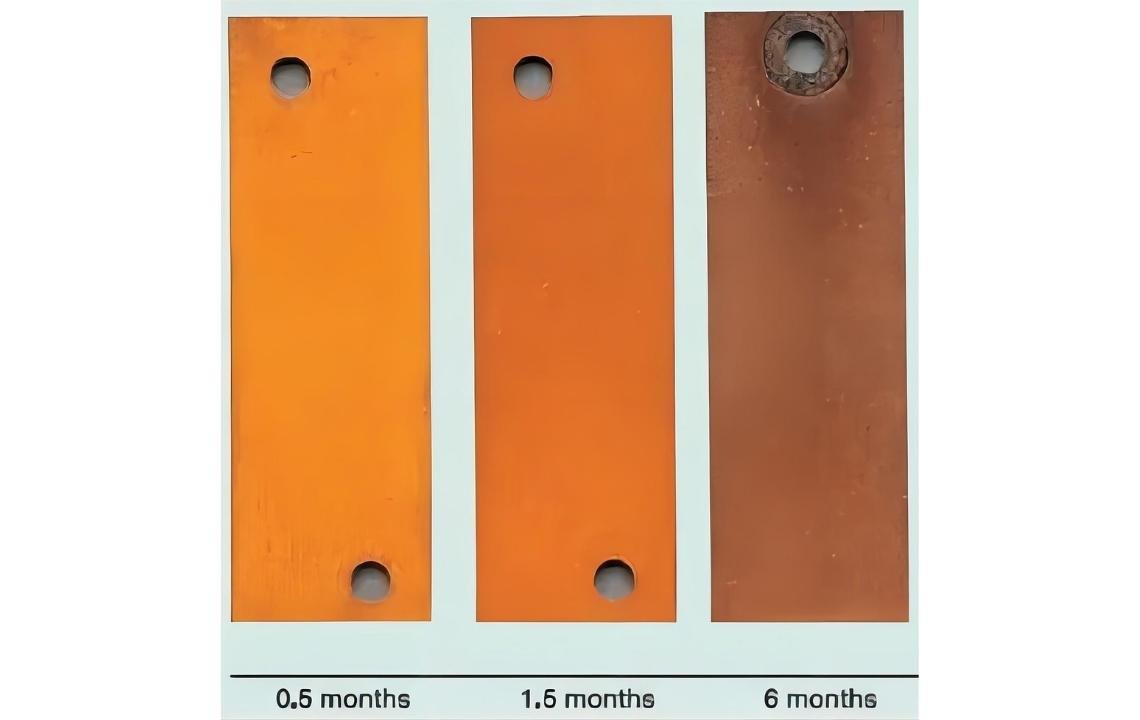

What is the Difference of the Rust and Corrosion? Why the Laser Rust Removal Machine is Not Good at Corrosion Layser Cleaning?

Under our definition, the oxidized layer formed of the metal material under normal environment within one year is rust, and the oxidized layer after more than one year we call it corrosion. Our laser rust removal machine is designed for the floating rust layer within one year which can be better removed. But under our resting,it doesn’t have good effective in removing the corrosive layer.

The reason why the effect of removing the corrosion layer is not good is that the corrosion layer is thick after years of accumulation and there is a fusion between the corrosion layer and the base material. But please don’t worry because our team is developing a technology that mix continuous laser tech and pulsed laser cleaning tech in order to remove thick rust and corrosion layers.

Some Real Application Scenarios and Stories from Customers

One of our customers from the local market, Foshan City. They mainly produce various machinery and equipment machine lathe, such as large laser cutting machine lathe, CNC machining center machine lathe, gantry milling machine lathe, etc. After welding the machine lathe due to the humid climate in South China, the surface of the machine tools are prone to floating rust, and need to do rust removal treatment before painting.

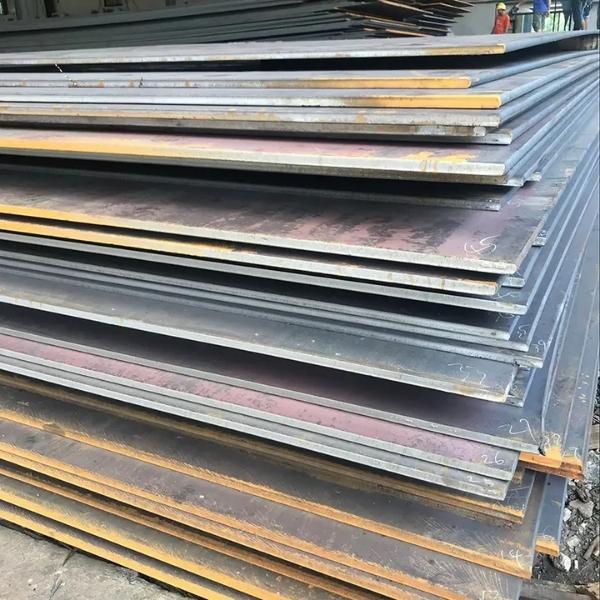

One of the largest distributors of raw steel sheets in the southern Indian city of Coimbatore bought our laser rust removal machine for simple rust removal before the raw material is sold.

There are many companies that do outdoor metal structure projects buy our metal descaling machine, outdoor metal structures are generally exposed to the air before painting and rust prevention, which will produce a lot of rust, and must do rust removal treatment before painting and rust prevention.

If you are a distributor of raw metal pipe materials. You can buy our laser rust removal machine, because if the storage environment is humid it will make your material rust. A simple rust removal treatment before selling will not only give a good impression to your customers, but also maybe sell for a better price.

Some Pictures from Our Customers

- Samples

- Data Sheet

- Reminder

| LASER RUST REMOVAL MACHINE | |||

| Laser Power(CW LASER) | 1000w | 1500w | 2000w |

| Model Number | MZ-1000R | MZ-1500R | MZ-2000R |

| Laser Cleaning Width(Adjustable) | 20-300MM | 20-300MM | 20-300MM |

| Laser Wave Length | 1064um±5 | 1064um±5 | 1064um±5 |

| Laser Fiber Cable Length | 10M | 10M | 10M |

| Laser Power Adjustable Range | 10-100% | 10-100% | 10-100% |

| Fiber Laser Beam Quality | Continuously/Modulated | Continuously/Modulated | Continuously/Modulated |

| Working Temperature | 15~35°C | 15~35°C | 15~35°C |

| Working Humidity | <70% Without condensation | <70% Without condensation | <70% Without condensation |

| Power Supply | 220V/50Hz | 220V/50Hz | 380V/50Hz |

| Total power | 5KW | 7KW | 9KW |

| Cooling Way | Water Cooling | Water Cooling | Water Cooling |

Please confirm the substrate to be cleaned with our technical team before confirming your order, there is a possibility that the laser rust removal machine may damage the substrate, please contact us for more information.

Related Product

Because continuous fiber laser can not control the thermal effect well and may heat and injure the surface of the substrate.

1.Electricity consumption

2.Protective windows of the focus lens

3.Pure water of the water chiller

Yes ,there are more than 20 countries that we have partner there.Please contact us for visiting.

We provide 2-year warranty for the whole machine except for consumables

My partner there will provide installation service on site or my engineer here will support you online to connect everything.